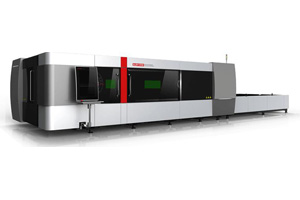

GS-G Fiber Laser Cutting System (Flat Sheet and Tube Processing All in One Machine)

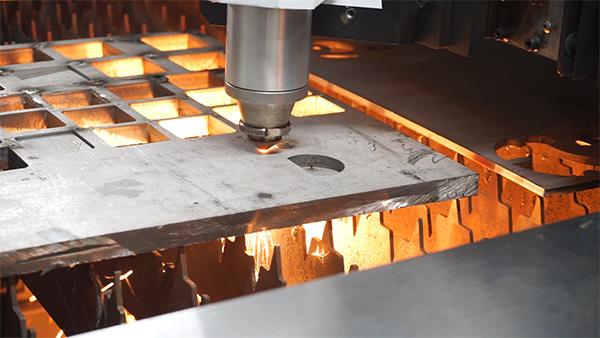

Two combined technologies maximize the cutting flexibility when it comes to sheet metal processing. Precise laser beam control and the proven fiber laser are combined in a machine to meet high demanding laser cutting requirements. All these enable the metal laser cutter specially suitable for processing flat, tube, channel, and angle profile, all with a single machine, realizing lower costs and maximized productivity.

In order to meet different needs, Glorystar Laser offers laser cutting machine in three optional working areas and a power of 500W-4000W.

- The GS-G laser cutter features an IPG laser, with a low energy consumption and long lifespan.

- The optical fiber transmission for optical setup requires no complex reflectors or other light guide systems, ensuring a simple optical set up and stable structure.

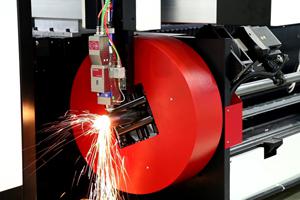

- The quick and simple transition from processing sheet metal to tubes maximizes the processing flexibility

- High-precision rack and pinion, highly stable reducer and servo motor for precise and efficient laser cutting.

- Featuring an open design, all laser cutting operations can be clearly viewed.

- Space and cost savings

Featuring with compact structure, the laser metal cutting machine occupies less space. This fiber laser cutter is a commonly used laser machine type because of its low investment and operation cost, and easy operation.

- Maximized processing flexibility

The quick and simple transition from processing sheet metal to tubes maximizes the processing flexibility.

- Automatic lubricating system

The automatic oil injection system comes with 8 automatic lubrication points. With high automation, each of them will be automatically injected with 0.1CC lubricating oil every 3 hours

- Patented design

The laser tube cutting machine comes with a self-developed electrically driven chuck with automatic self-centering function. The chuck adapts to the geometry of every tube and profile, so that no chuck jaw changing is needed during the whole laser cutting processing, greatly enhancing the cutting efficiency and simplifying the operation. This self-centering clamping system can complete pipe clamping and loosening in a quick manner, and the clamping force is allowed to quickly adjust according to the wall thickness of the pipe.

| Model | GS-3015G | GS-4015G | GS-4020G | GS-6015G | GS-6020G |

| Maximum processing dimensions (mm) | 3000*1500 | 4000*1500 | 4000*2000 | 6000*2000 | 6000*2000 |

| X-axis travel | 1520 | 1520 | 2030 | 2020 | 2020 |

| Y-axis travel | 3020 | 4020 | 4050 | 6020 | 6020 |

| Z-axis travel | 270 | 270 | 270 | 270 | 270 |

| CNC system | CYPCUT | CYPCUT | CYPCUT | CYPCUT | CYPCUT |

| Geometric positioning accuracy of X/Y axis | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repeatable positioning accuracy of X / Y axis(mm) | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Maximum composite positioning speed of X/Y axis | 70-100m/min | 70-100m/min | 70-100m/min | 70-100m/min | 70-100m/min |

| Maximum combined acceleration of X/Y axis | 0.6-1.0G | 0.6-1.0G | 0.6-1.0G | 0.6-1.0G | 0.6-1.0G |

| Circumcircle size | 20-220 | 20-220 | 20-220 | 20-220 | 20-220 |

| Cutting pipe length | 3m & 6m | 3m & 6m | 3m & 6m | 3m & 6m | 3m & 6m |

| Chuck cutting size (Manual/Automatic) | 20-190(120) 20-220 20-340 | 20-190(120) 20-220 20-340 | 20-190(120) 20-220 20-340 | 20-190(120) 20-220 20-340 | 20-190(120) 20-220 20-340 |

Glorystar Laser Group

Glorystar Laser Group Dongguan, Shenzhen, Suzhou