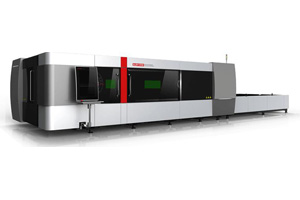

Laser Cutting System

Compared with plasma cutting and flame cutting, laser cutting features high cutting size precision, little thermal deformation, narrow slot width, and wide cutting materials.

Since its establishment, Glorystar Laser Group has been dedicated to the R&D, and manufacture of laser cutting system for decades. In order to ensure the quality of laser cutting machines, 21 quality-inspection procedures will be performed. Providing superior quality fiber laser system is our commitment to our customers across the globe.

Advantages of our Laser Cutting System- laser transmitter

High power IPG solid-state laser transmitter, equipped with a power automatic monitoring device and featuring a power stability of ±1%-±2%.

- Laser head

Laser head with self-adaption optical system can adjust the size of the laser spot automatically. A non-contact sensor is equipped to ensure a constant distance between nozzle and processed materials, resulting in good processing effects even when the workpiece surface is not smooth.

- Body

The high-strength welded machine body features specially processed aluminum beams resulting in good rigidity and high strength.

- Drive system

A double side drive structure, high precision pinion and rack and linear guideway system deliver high installation accuracy, large drive torque, small transmission error and outstanding dynamic characteristics.

- Control system

Under an European control system, the use of TwinCAT CNC motion control software, related motion control hardware and high speed EtherCAT fieldbus technology guarantee high dynamic properties and maximizes the potential energy of laser transmitter to deliver outstanding speed and efficiency.

- Programming software

Spanish Lantek/ Italian Libellula professional laser cutting automatic programming nesting software is user friendly.

-

- NAVSTAR Fiber Laser Cutting Machine (High Power)With high-quality components, ultra-fast cutting speed and high cutting size precision, high power fiber laser cutting machine of NAVSTAR Series brings you excellent cutting quality.

- Read More

-

- GS-CE Fiber Laser Cutting Machine with Shuttle PlatformBenefited from the enclosed sealed design, cost-effective configurations, and optimized positioning system, exceptional reliability and safety are provided for your laser cutting jobs.

- Read More

-

- GS Fiber Laser Cutting MachineGS series single table fiber laser cutting machine features open design, allowing for easy access from all four sides. This makes loading and unloading from all four sides even during processing. This metal cutting machine is suitable...

- Read More

-

- GS-TG Tube/Pipe Laser Cutting MachineWith highly intelligent cutting system, GS-TG Series fiber laser cutting machine is specially designed for cutting tube & pipe. Due to high automation and easy operation, operation and labor costs are greatly reduced, achieving a combination of high cutting efficiency and high cutting quality.

- Read More

-

- GS-G Fiber Laser Cutting System (Flat Sheet and Tube Processing All in One Machine)GS-G fiber laser cutting machine provides a highly efficient metal cutting solution due to quick and simple transition from flat sheet to tube or pipe cutting. With space and cost savings, this metal cutting machine is an ideal choice in the metal processing industry.

- Read More

-

- GS-CEG Fiber Laser Cutting System (Flat Sheet and Tube Processing All in One Machine)The fiber laser cutting machine is integrated with both metal sheet and tube & pipe cutting functions, greatly enhancing working efficiency and reducing cost in initial investment. Using servo motor, precise cutting in a stable manner is achieved.

- Read More

-

- CO2 Laser Engraving Cutting MachineCO2 laser engraving cutting machine adopts advanced DSP control technology with strong anti-interference ability, providing fast cutting speed and high cutting precision. Designed with USB port...

- Read More

Glorystar Laser Group

Glorystar Laser Group Dongguan, Shenzhen, Suzhou