Tube Cutting

Traditional metal tube processing only refers to cutting, and there are few complicated process requirements. However, with the diversification of the market, the requirements for tube cutting are getting higher and stricter. Traditional cutting methods can also achieve the cutting effect, such as sawing machine cutting, abrasive cutting and spark cutting. But they offer a low processing efficiency, numerous rough edges, and require a secondary grinding process, which do not meet customer requirements for a high output and high quality. That is reason why Glorystar Laser combines laser cutting technology and tube cutting to offer our customers a better, broader future development within the tube cutting field.

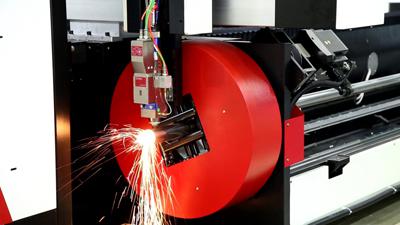

Fiber laser cutters are a precision equipment type that uses a laser to cut, punch, or hollow out a tube. They can be used to cut box iron, angle iron, joist steel, H-beams and other tubes in a variety of shapes and materials. Due to the non-contact processing mode, there is no pressure on the tube wall and it will not cause the outside surface of the tube to deform during the whole processing process. This ensures the thin walled tube will feature a better processing effect.

Glorystar Laser has been involved in the production of laser cutters for more than 30 years, and engages more than 80 R&D designers to ensure we can offer our customers the best products to meet their needs. Shown below are a few tube laser cutters we’ve previously produced, and we welcome customer inquiries regarding customization options.

Cutting samples Glorystar Laser Group

Glorystar Laser Group Dongguan, Shenzhen, Suzhou