Fully Automatic Medical Face Mask Making Machine

The mask making machine is applicable to automatic production of medical face masks of 3-4 layers. All operations from raw material feeding, cutting, forming, edge banding, and nose wire attaching are carried out in an automatic manner. Our face mask machine features high performance, high production speed, easy operation and maintenance. It's driven by servo motor, and controlled by PLC system, providing precise operation and control. The mask making machine can be paired with different earloop welding machines to product face masks with inner and outer earloops.

Cutting samples Features- Reduced cost and improved production efficiency due to fully automatic production

- Occupies less space due to the machine dimensions of 4320mm(L)×3360mm(W)×2000mm(H)

- High production speed up to 70,000 pcs/day under 24h continuous running

- The mask making machine features PLC control, ultrasonic system, and photoelectric sensing system, allowing for high stability and low failure rate.

- Constructed with aluminum alloy for high durability

| Model | GS-APA (for making inner earloop mask) | GS-AP1 (for making outer earloop mask) |

| Mask Specification | 175*95mm | |

| Qualification Rate | 98% | |

| Failure Rate | 2% | |

| Machine Dimensions | 5000mm(L)×3500mm(W)×2000mm(H) | 4320mm(L)×3360mm(W)×2000mm(H) |

| Exterior Color | White or customized | White or customized |

| Weight | ≤2000kg | ≤800kg |

| Factory Floor Load | ≥500KG/m2 | ≥300KG/m2 |

| Power Supply | 220VAC±5﹪, 50HZ | AC220V±5%, 50HZ |

| Rate Power | 15KW | ≤8KW |

| Air Pressure | 0.5~0.7 Mpa | |

| Ambient Temperature | 10~35℃ | |

| Ambient Humidity | 5-35%HR | 30-60%RH |

| Working Environment | Non-flammable, non-corrosive gas, dust free (Cleanroom with class 100,000 or above) | Non-flammable, non-corrosive gas, dust free |

Semi-Automatic Mask Making Machine

The mask making machine is constructed with a raw material feeding station and aluminum alloy machine body with high durability. After material feeding, the operations are all automatically preformed, including folding, edge banding, nose wire attaching, ultrasonic welding, cutting, and output. Due to the servo motor, precise control and operation is achieved. This mask machine features high production efficiency, high durability, easy operation and maintenance. It can be paired with different earloop welding machines to product face masks with inner and outer earloops.

Features- Adjustable production speed, easy to operate, high running stability

- High production speed up to 120-140 pcs/min

- Durable earloop welds due to high quality ultrasonic welding process

- Touch screen design allows for easy operation.

- The earloop ultrasonic welding machine is designed with an automatic alarm function, allowing for automatic machine stop in emergency situations.

- Mask output can be easily calculated by means of the photoelectric sensing system.

| Mask Specification | 175*95mm |

| Qualification Rate | 98% |

| Failure Rate | 2% |

| Machine Dimensions | 3722mm(L)×800mm(W)×2000mm(H) |

| Exterior Color | White or customized |

| Weight | ≤400kg |

| Factory Floor Load | ≥300KG/m2 |

| Power Supply | AC220V±5%, 50HZ |

| Rate Power | ≤3KW |

| Ambient Temperature | 10~35℃ |

| Ambient Humidity | 30-60%RH |

| Working Environment | Non-flammable, non-corrosive gas, dust free |

| Names | Quantity | Notes |

| Raw material feeding station | 1 set | accommodates at most 4 rolls fabric + 1 roll nose wire |

| Folding unit | 1 set | |

| Nose wire feeding unit | 1 set | Width≤3mm |

| Edge banding unit | 1 set | |

| Mask body die cutting | 1 set | |

| Feeding unit of mask body | 1 set | |

| Ultrasonic system | 1 set | |

| Control system | 1 set | PLC+HMI |

Semi Automatic Outer Earloop Welding Machine

As an important machine of the mask production line, this ultrasonic welding machine is specially designed for welding the earloops on the outside mask body, with production capacity of 30-50 pcs/min. The earloop welding machine can be paired with a mask making machine to realize automatic production of various protective face masks.

Features- Controlled by the servo motor, high running stability and precise operation are achieved.

- Automatic alarm function provides high operation safety.

- Automatic control for all operations allows for high production efficiency.

- Easy to use touch screen for operation

- Adjustable earloop weld strength

| Mask Specification | 175*95mm |

| Qualification Rate | 97% |

| Failure Rate | 2% |

| Machine Dimensions | 3268mm(L)×1038mm(W)×1520mm(H) |

| Exterior Color | White or customized |

| Weight | ≤300kg |

| Factory Floor Load | ≥300KG/m2 |

| Power Supply | AC220V±5%, 50HZ |

| Rated Power | ≤5KW |

| Air Pressure | 0.5~0.7 MPa |

| Ambient Temperature | 10~35℃ |

| Ambient Humidity | 30-60%RH |

| Working Environment | Non-flammable, non-corrosive gas, dust free |

| No. | Names | Quantity | Notes |

| 1 | Chain driven raw material unit | 1 set | |

| 2 | Earloop welding unit | 1 set | |

| 3 | Unloading conveyor | 1 set | |

| 4 | Ultrasonic system | 2 sets | |

| 5 | PLC control system | 1 set | PLC+HMI |

Semi Automatic Inner Ear-Loop Welding Machine

Features

Features

- Adjustable production speed, easy to operate, high running stability

- High production speed up to 40-60 pcs/min

- Durable earloop welds due to high quality ultrasonic welding process

- Touch screen design allows for easy operation.

- The earloop ultrasonic welding machine is designed with an automatic alarm function, allowing for automatic machine stop in emergency situations.

- Mask output can be easily calculated by means of the photoelectric sensing system.

| Machine Body | Aluminum alloy |

| Machine Dimension(L*W*H) | 2900(L)*950(W)*1550(H)mm |

| Production Capacity | 40 - 60 pcs/min |

| Layer of the Mask | 3-4 layers |

| AC Voltage | 220V |

| Brand Name | Glorystar |

| Power | 1.5KW 20HZ |

| Air Pressure | 0.5-0.6Mpa |

| Weight | About 350KG |

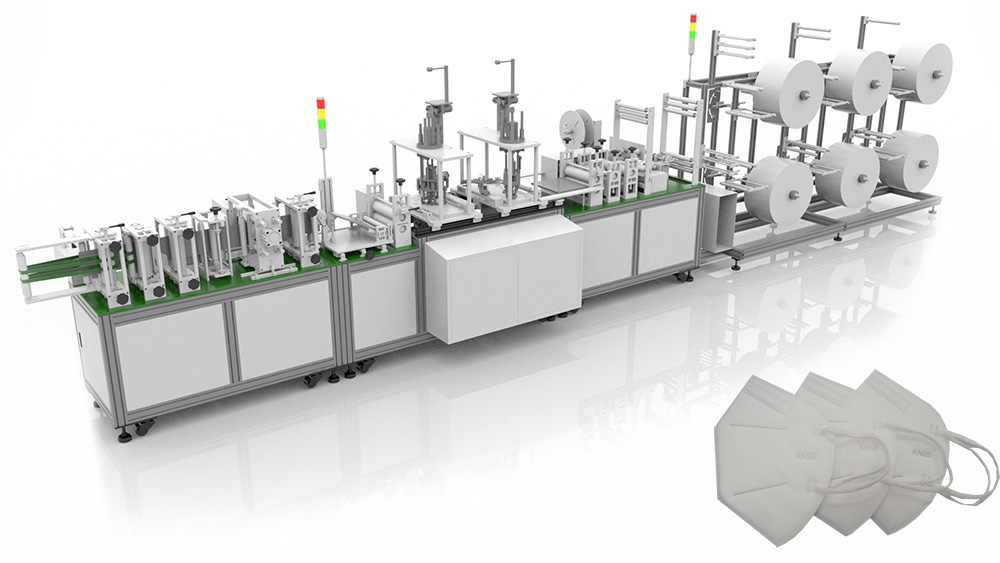

Automatic Mask Making Machine

The automatic mask making machine is used for the production of 3D foldable face protective masks such as KN95, N95. All operations are automatically preformed, including raw material feeding, cutting, folding, forming, nose wire attaching, and earloop welding. The logo can be either printed or attached onto the face masks upon request.

Features- Due to full automatic control, all operations from fabric feeding to final mask output are automatically carried out, significantly enhancing production efficiency.

- High production speed up to 50-60 pcs/min

- The mask body is thermostatically shaped, ensuring no damage to the materials.

- This enables it to maintain its high filtration performance.

- Ultrasonic welding paired with cooling function provides neat, clean and aesthetically good welds.

- The mask making machine features an PLC running system, allowing for few points of failure and long service life.

| Machine Dimensions | 9500mm(L)x1500mm(W)x1900mm(H) |

| Exterior Color | international standard warm ash 1C or customized |

| Weight | ≤2000kg |

| Factory Floor Load | ≤500KG/ m2 |

| Power Supply | 220V, 50HZ (at the rated power of 15KW) |

| Air Pressure | 0.5-0.7 MPa |

| Working Environment | Temperature: 10-35℃, humidity: 5-35%HR; non-flammable and non-corrosive gas, dust free (Cleanroom with class 100,000 or above) |

| Symmetrical Accuracy after Folding | +/-1mm |

| Machine Failure Rate | 2% |

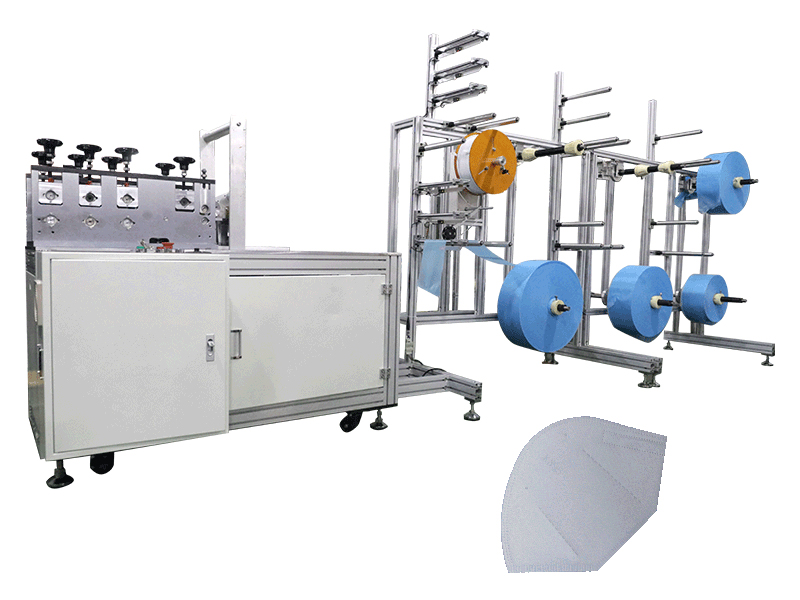

KN95 Semi-Automatic Mask Making Machine

KN95 mask making machine is used for the automatic production of KN95 protective face masks consisting of 4-5 layers of non-woven fabric, melt-blown cloth, hot air cotton, and other filter materials. The face mask machine is comprised of fabric feeding station, heavy duty machine body, and mask discharging station. Various operations can be carried out in the machine, including fabric feeding and cutting, blank mask forming, and nose wire attaching. In order to improve production efficiency, an earloop welding machine can be paired with the mask making machine to form a complete KN95 mask production line.

Features- Occupies small factory area due to the machine dimensions of 5460*1060*2000mm

- Production speed: 120-140 pcs/min

- Adjustable speed, easy to operate, and high running stability

- Photoelectric sensor assisted detection prevents machine failures and reduces downtime, greatly enhancing production efficiency.

- PLC control provides high stability

- Mask output can be easily calculated by pressing one button.

| Machine Dimensions(L*W*H) | 5460*1060*2000mm |

| Weight | 600KG |

| Voltage | AC 220V 50Hz |

| Capacity | 120-140 pcs/min |

Glorystar Laser Group

Glorystar Laser Group Dongguan, Shenzhen, Suzhou